HBD Automatic Cement Blocks Factory – SINAW, OMAN

Concrete Block:

A concrete block is a block made of concrete. To raise the quality of the blocks you need to apply vibration and force to make the mortar as compressed as possible. A

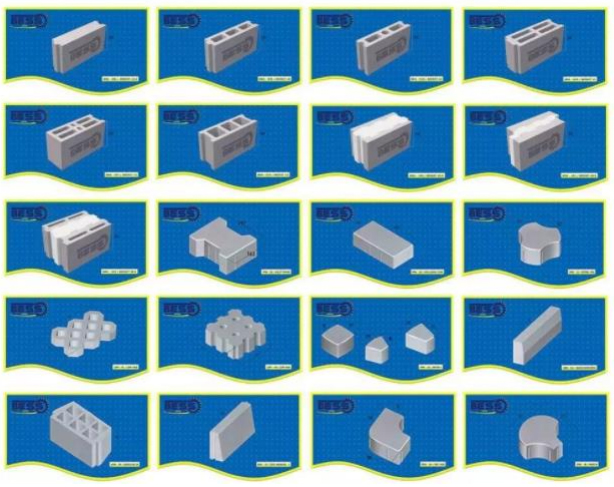

concrete block is a general name and includes different types of blocks. Below you can see some examples of concrete blocks.

* Hollow concrete blocks with different shapes and sizes.

* Solid concrete blocks with different shapes and sizes.

* Paving blocks with different shapes, sizes, and colors.

* Hollow floor blocks

In all the items you can see concrete included but and you may ask what concrete is. Concrete is formed with aggregates, water, and Portland cement which is usually in

the form of powder. There are different standards for the mixture ratio of the 3 items. Also, admixtures are available to add extra features to the concrete.

Note that there is a difference between additive and admixture. Additives are added to cement during manufacturing to get new properties for cement but admixtures are added to concrete while mixing to get new features. Depending on your country you can use different aggregates as well, most common aggregates are limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

Concrete Block Manufacturing Process:

The concrete block manufacturing process has different steps based on the system you are producing them. The concrete block manufacturing process can be manual, semiautomatic, automatic, and full-automatic depending on your demand, country, and budget. Below you can find about Fully Automatic Block Manufacturing Process, because we’re using this method for our manufacturing.

Full-automatic concrete block manufacturing process:

The difference between automatic and full-automatic methods is that in the automatic method you need an operator to operate the machine but in a Full-automatic concrete

block machine, the machine operates automatically. This design is suitable for developed countries where labor cost is high and the land is also expensive.

Concrete Block Machine:

These machines are also called “interlocking brick machines”. There are different types of concrete block machines available in the market. Some of them are mobile and some of them are stationary. In this project, we’re using mobile machine, named “Lorev – BL1020A-Lunga” (Made in Italy)..